Three-Wavelength Diode Laser Modules - Precision Meets Versatility

A three-wavelength diode laser module is a system designed to produce three distinct wavelengths of laser light within a single device. This eliminates the need for multiple separate lasers, making it easier to switch between or combine wavelengths in various applications.

Three diode lasers that emit different wavelengths can be combined through optical components such as dichroic mirrors or fiber combiners, resulting in a unified output with multiple wavelengths available for independent or simultaneous use.

Our triple-wavelength laser modules offer system simplicity, combining advanced performance with seamless switching between wavelengths or simultaneous use.

Space-Saving Design

Improved Accuracy

Increased Efficiency

Broad Application Range

Multi-Wavelength Flexibility

Cost Savings

Due to these advantages, many industries consider three-wavelength diode laser modules essential to their workflows.

When selecting a three-wavelength laser module, key factors influence both system performance and ease of use:

Wavelength Combinations

Cooling System

Output Power

Module Package Options

Beam Quality

Application Specific Metrics

Choosing a manufacturer that checks all these boxes ensures that your investment in a three-wavelength diode laser module pays off in terms of both performance and reliability.

Three-wavelength diode laser modules have a broad range of applications across different sectors.

Medical and Scientific Research

Fluorescence Microscopy

Spectroscopy

Optogenetics

Industrial and Engineering

Material Processing

Metrology

Telecommunications

Environmental and Agricultural

Remote Sensing

Agriculture

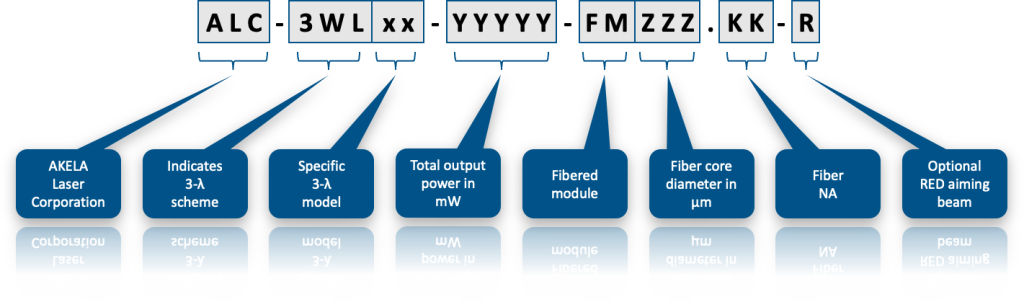

Part number structure

Examples of possible combinations

Given the numerous possible combinations, we provide examples of various configurations along with a selection of actual data sheets.

Sample Data Sheets

FAQs About Three-Wavelength Laser Modules

A three-wavelength diode laser module integrates three individual laser diodes—each operating at a distinct wavelength—into a single, compact system. These wavelengths are optically combined using precision components such as dichroic mirrors or fiber combiners, allowing either simultaneous or independent output. This eliminates the need for multiple laser systems and streamlines applications requiring multiple wavelengths.

Three-wavelength modules offer:

- Simplified optical alignment

- Reduced footprint and cabling

- Lower power consumption and cooling demands

- Enhanced portability and system integration

These factors lead to greater reliability, faster deployment, and cost savings in complex multi-wavelength applications.

Common combinations include wavelengths in the visible and near-infrared range—such as 405 nm, 520 nm, 635 nm, or 808 nm, 980 nm, 1064 nm. Custom configurations are available based on your specific application needs. Reach out to discuss tailored wavelength and power options.

Akela offers both fiber-coupled and free-space output configurations. Fiber-coupled options support single-mode, multimode, or polarization-maintaining fibers and are ideal for plug-and-play integration into microscopes, optical benches, or OEM systems.

Consider the following:

- Wavelengths required for your materials or targets

- Beam quality (single-mode vs. multimode)

- Power level (mW to watts per channel)

- Modulation needs (analog, TTL, or digital)

- Cooling and thermal performance

- Mechanical format or fiber-coupled output

Our engineers can help guide you to the ideal configuration.

These modules are used across:

- Biomedical and Life Sciences: Fluorescence microscopy, optogenetics, flow cytometry

- Spectroscopy and Metrology: Multi-wavelength sensing, interferometry

- Industrial Applications: Precision material processing, alignment, and inspection

- Environmental and Remote Sensing: Gas detection, vegetation analysis

A reliable manufacturer should offer:

- Deep photonics expertise

- Custom engineering for wavelength, power, and format

- Strict quality control – spectral accuracy, stability, durability

- Fast, responsive support before and after the sale

- Compliance with safety standards (e.g., FDA, CE, ISO)

- Timely delivery to meet project milestones

- Competitive pricing without compromising quality

Akela Laser checks all these boxes with U.S.-based engineering and global service reach.

Yes. We specialize in custom three-wavelength laser modules, including:

- Custom wavelength combinations

- Tuned output power levels

- OEM, benchtop, or fiber-coupled configurations

- Special housing, alignment, or integration features

- Advanced modulation or triggering support

- Let us tailor a solution that meets your exact system needs.